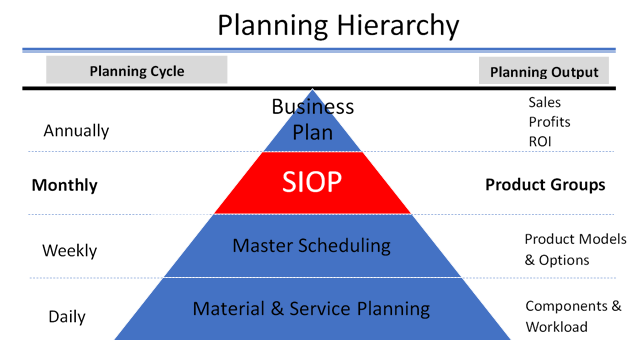

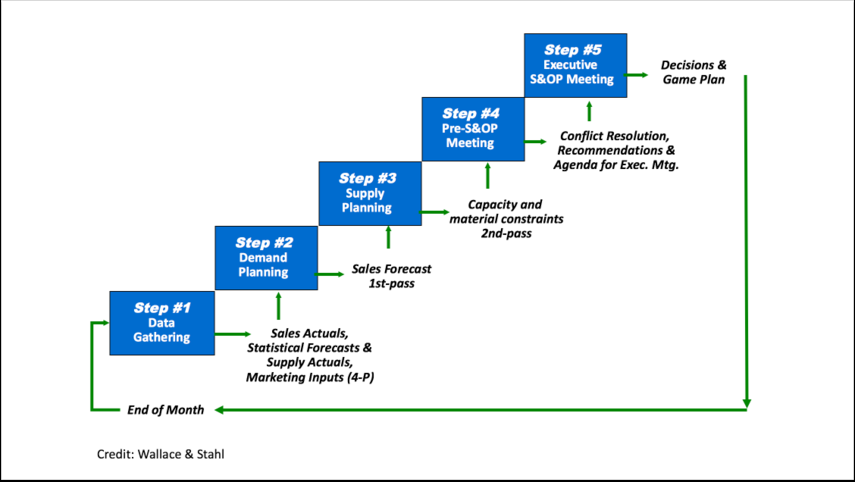

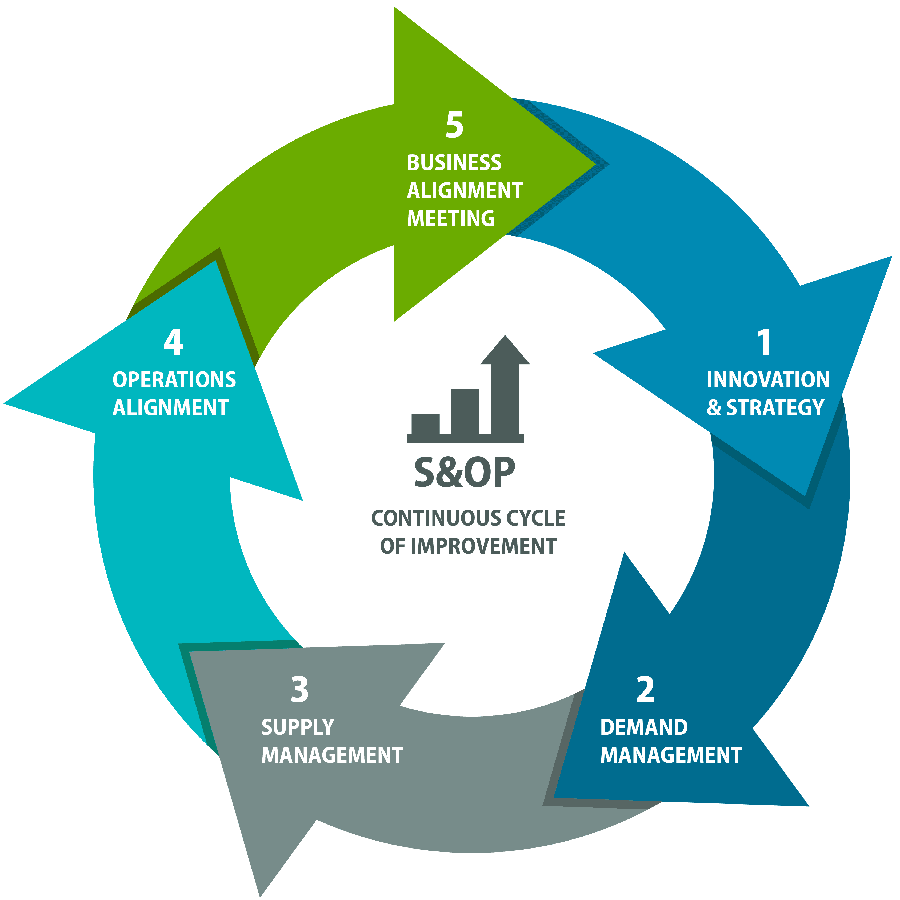

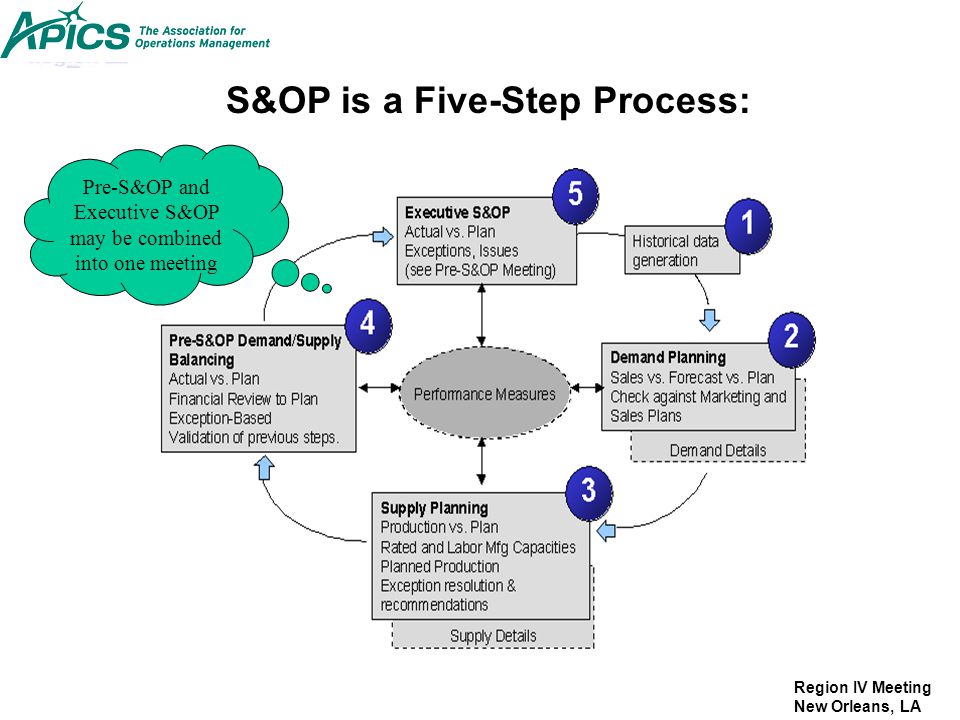

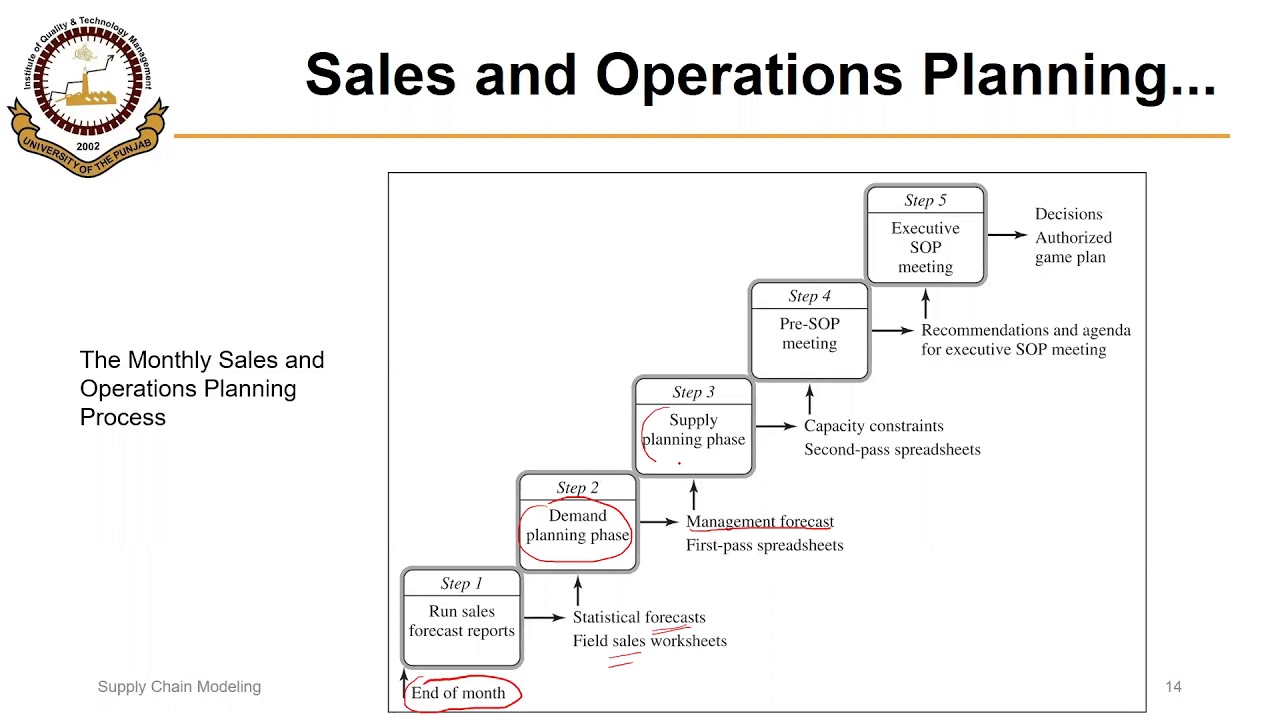

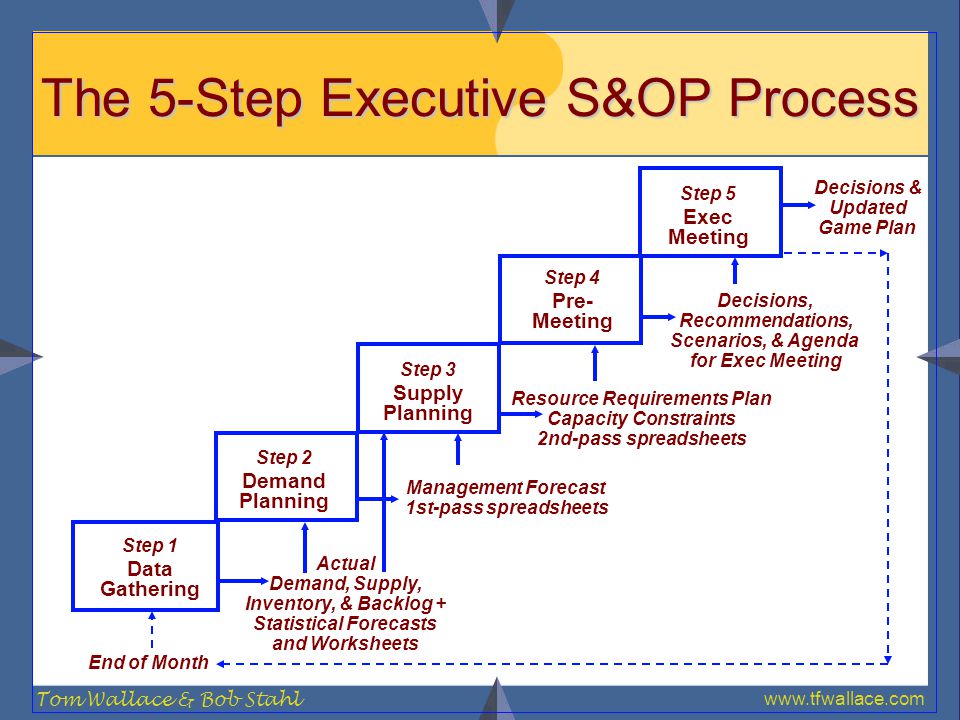

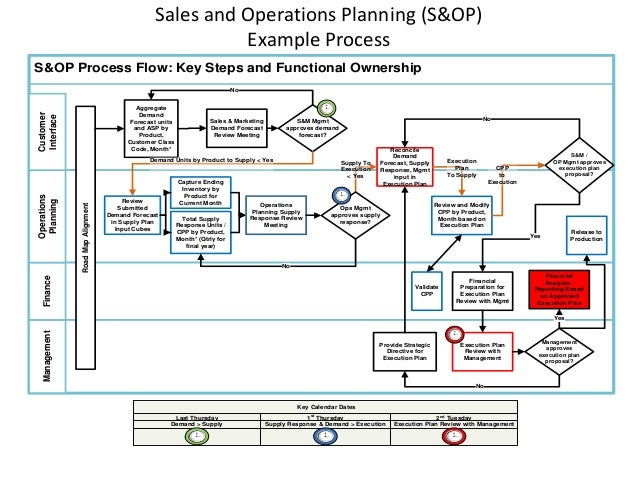

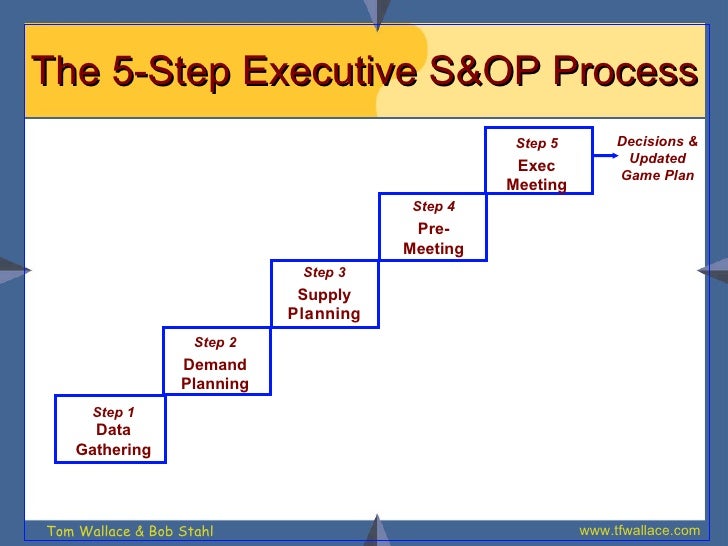

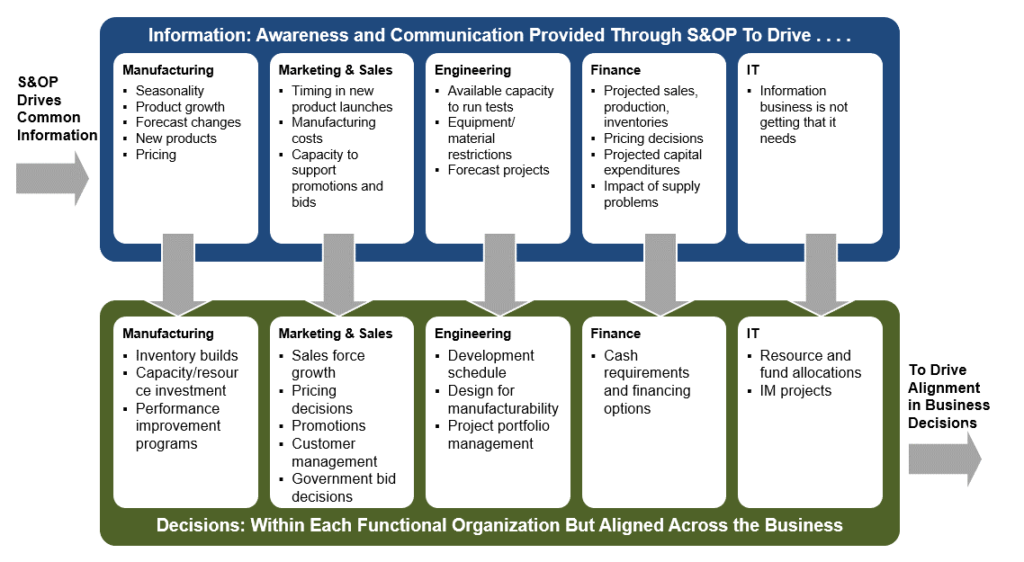

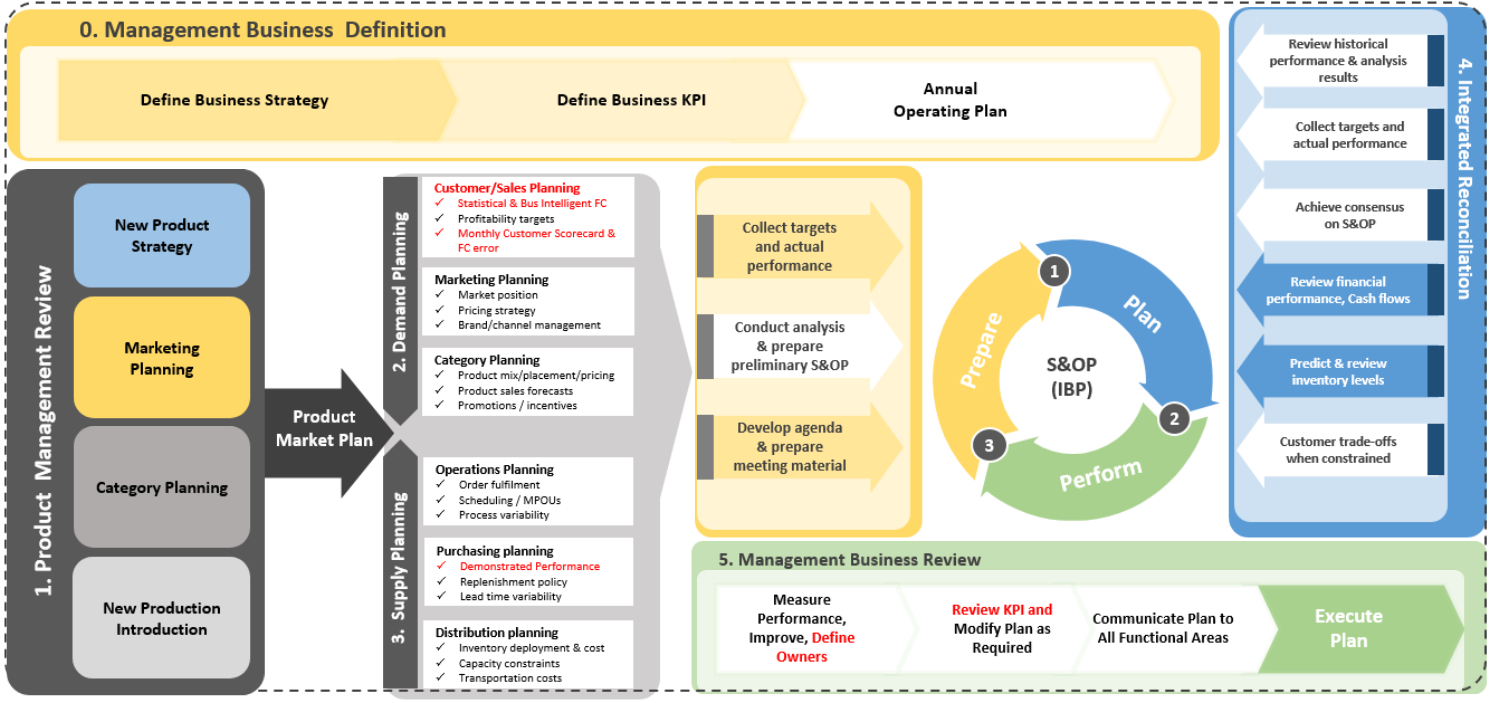

16 S&OP @ 100,000 Feet Executive S&OP A process to reconcile, agree upon, and communicate the company game plan Product Development (New Product Introduction) Finance (Dollars) Sales & Marketing (Units/$$ by product family) Operations (Units/Hours/Materials) 17Sales and Operations Planning is typically realized following a fivestep process that has a monthly or weekly frequency and is applied to product families Each of the five steps forming the S&OP process involves people belonging to different areas and the time horizon covered by their activities goes from 12 up to 18 or even 24 monthsFiveStep Process (Agenda & Critical Characteristics) Data Gathering & Statistical Analysis;

0以上 S Op Demand Planning Meeting What Is S Op Meeting Gambarsae6p5

5 steps s&op process

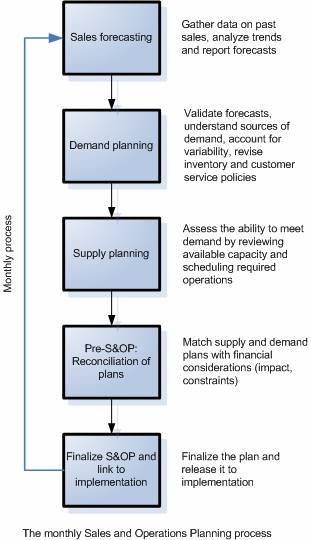

5 steps s&op process- Sales and operations planning (S&OP) is a business management process It involves all the functions of the business working together to manage the future supply chain as efficiently as possible It is intended to maximise revenue by planning ahead to ensure that customers orders are met as efficiently as possible S&OP is a monthly management process It provides a link between strategy and execution that engages senior management in a tangible way to make decisions in order to balance company goals and direction with sales and operational capability Getting to a to a level of maturity where this can happen is a tall order

What Is S Op How S Op Works Demand Planning Com

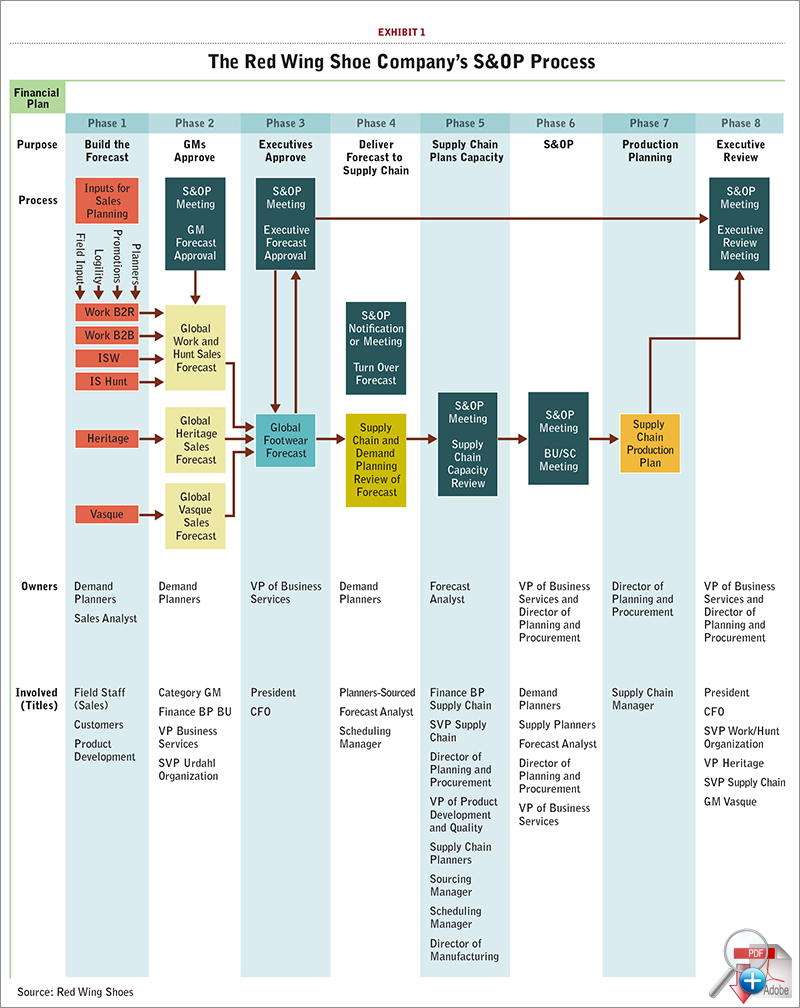

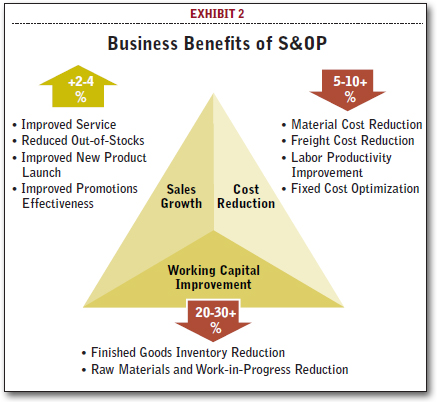

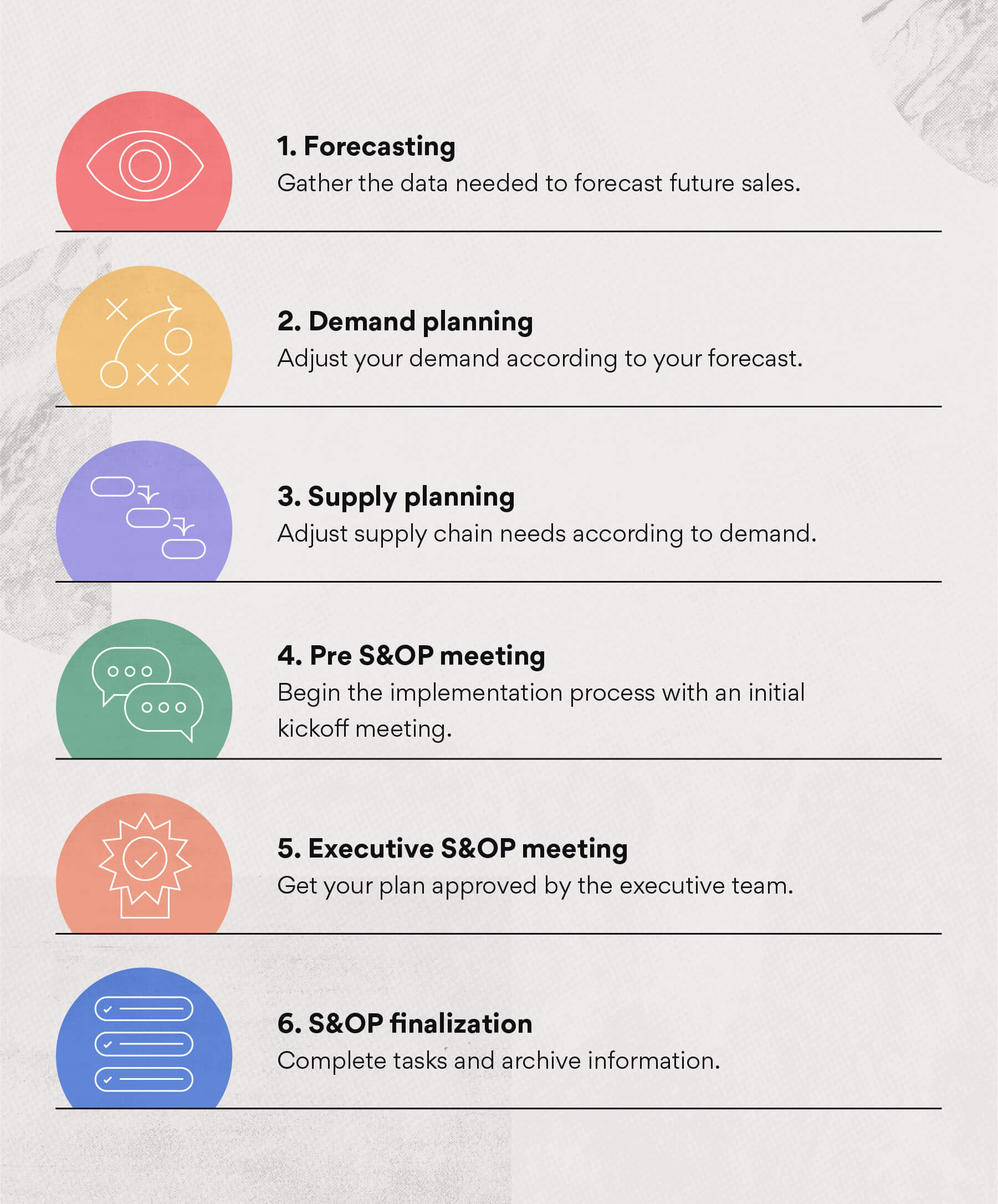

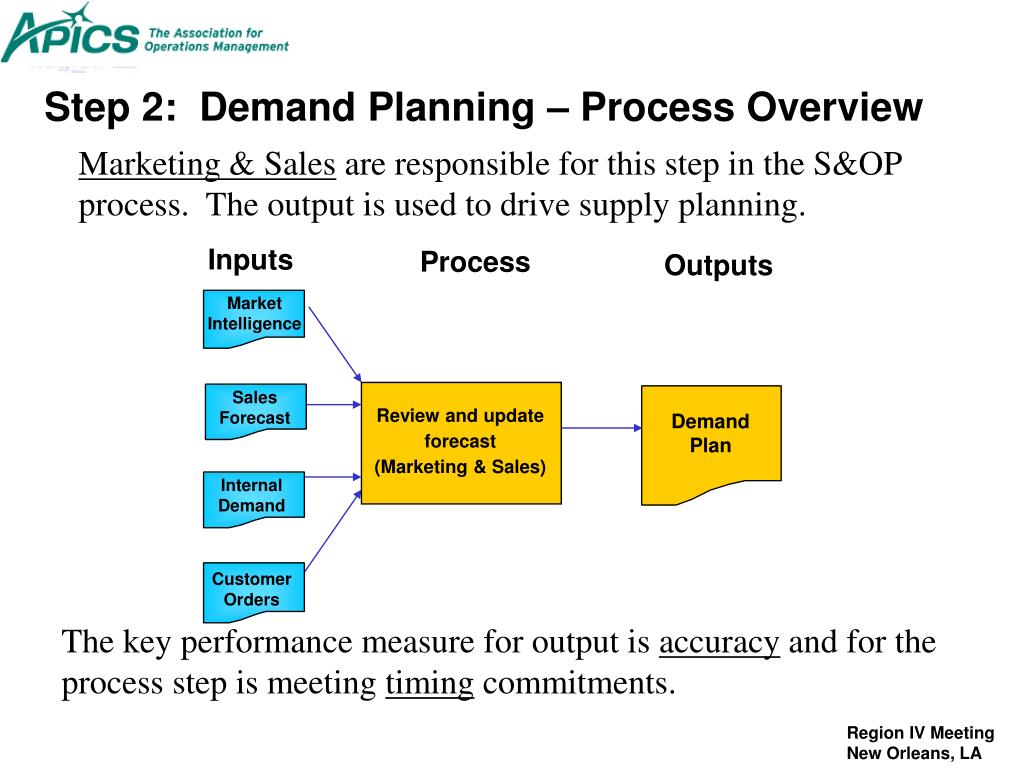

The S&OP process can be broken down into six essential steps data gathering and forecasting, demand planning, production planning, preSOP meeting, executive S&OP meeting, and the S&OP strategy implementation Sales and operations planning is a monthly business process enabling a company to determine the organizational goals It allows the organization to meet its operational, sales, and financial targets The process is typically the responsibility of a specific sales and operations planning team This includes the company's decision makers andO CPFR process is cyclic, S&OP steps are not redundant o CPFR involves the associated businesses and trading partners, S&OP involves only the various constituents from within the organization o CPFR is likely to manage the inventory more efficiently

S&OP Implementation process the 10 steps Case Study from FMCG industry New Zealand Also included with this document is a bonus zip of 41 Lean documents (includes templates, case studies, articles, posters, charts, and more)"There's no clearcut boundary, but I'd say that Phase 1 marks the start of S&OP and that your S&OP process reaches maturity in Phase 2Implementing a Sales and Operations Planning (S&OP) Process Step 1 Gather and Manage Data This step entails the collection of data on past sales, trend analysis, and assessments Step 2 Develop Demand Plan Demand planning includes validating forecasts, understanding sources

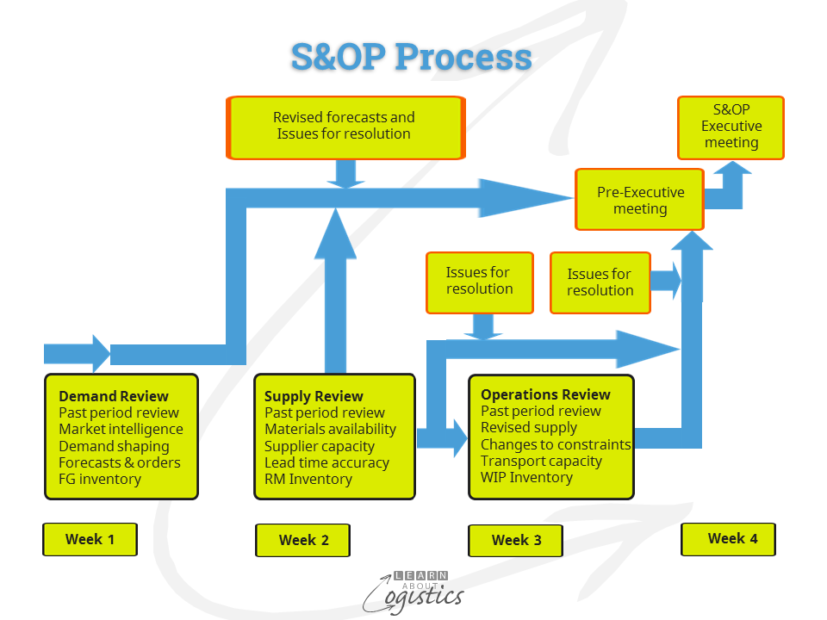

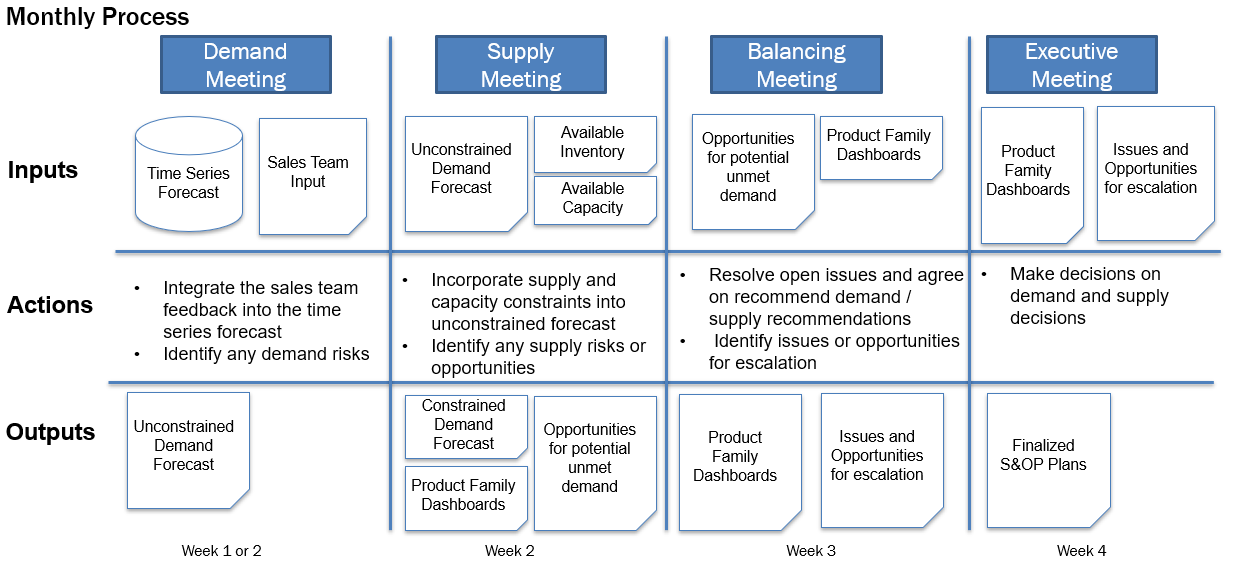

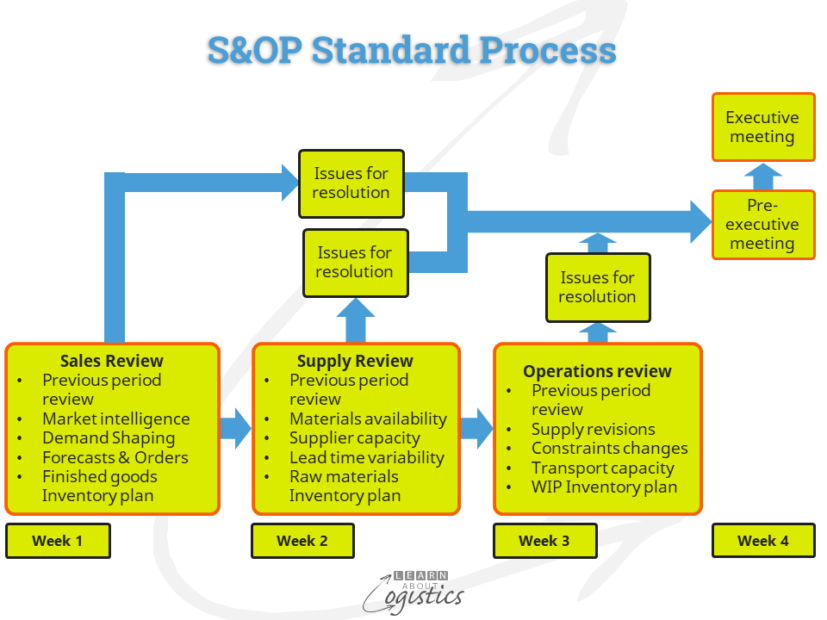

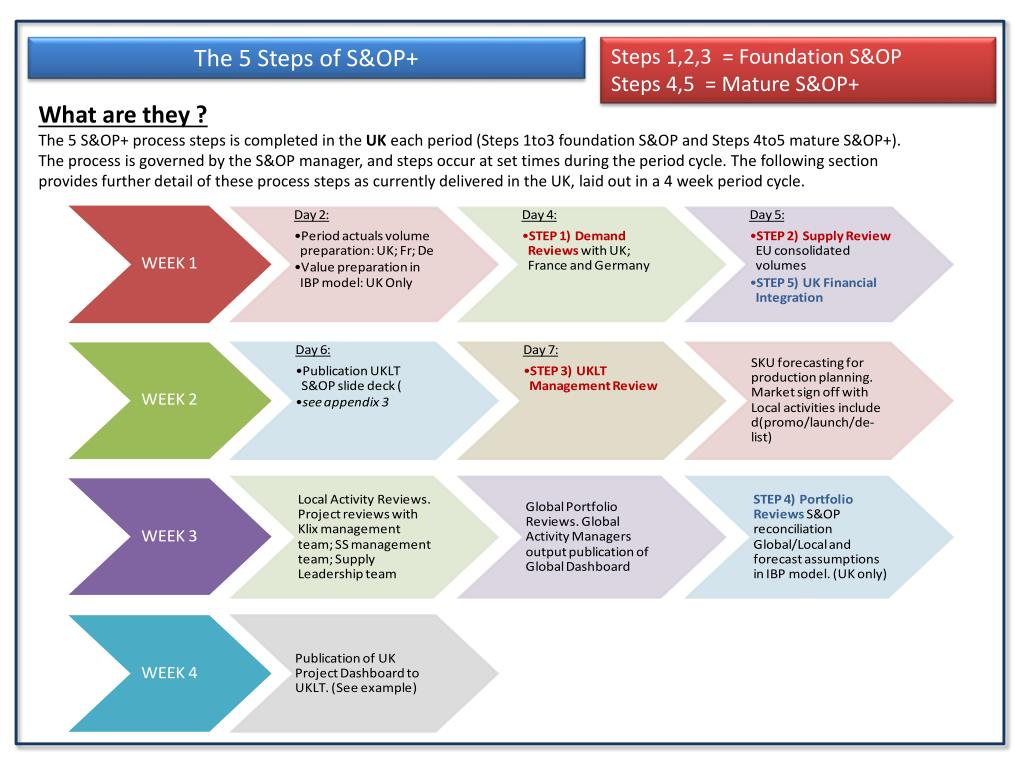

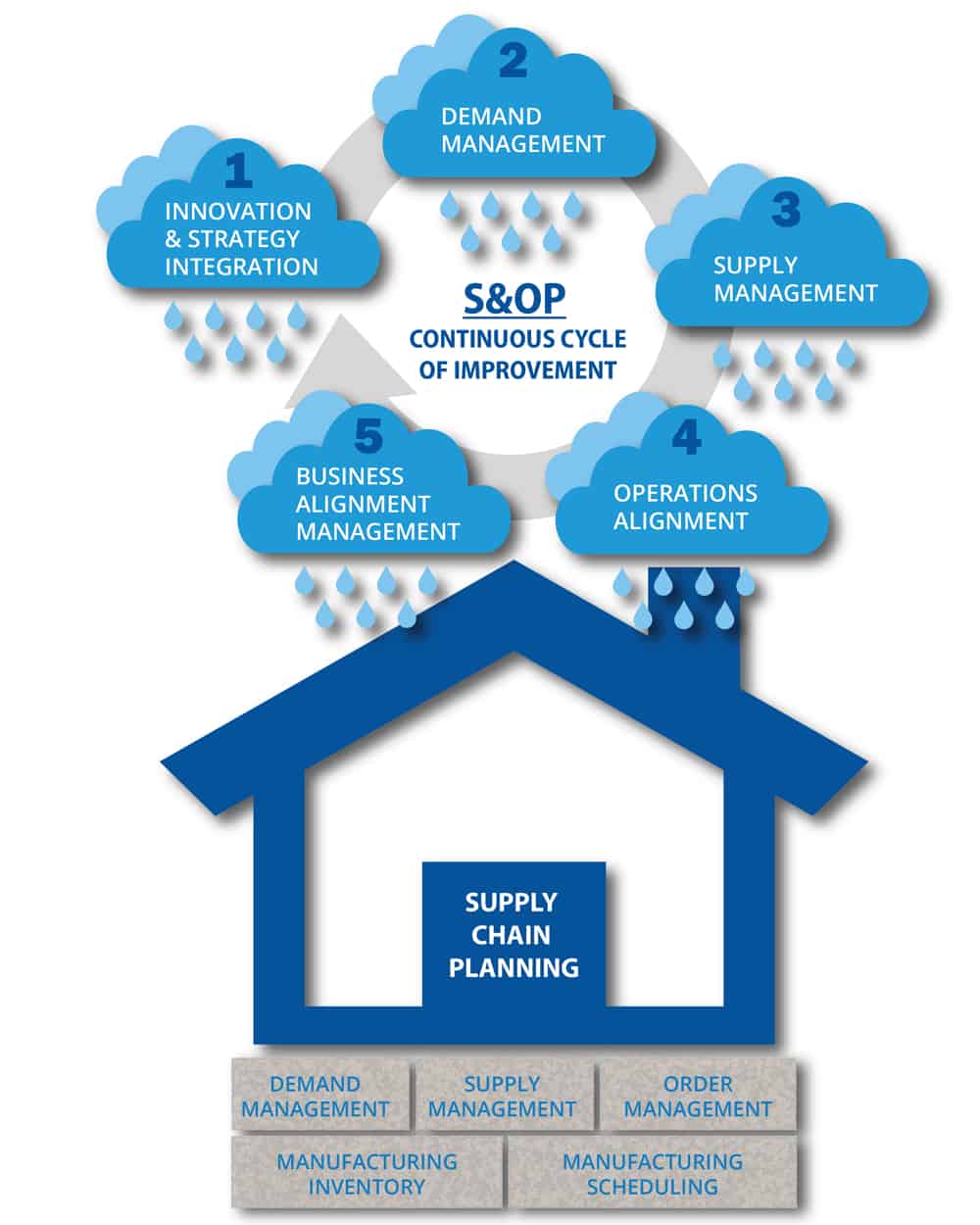

Highlevel results with respect to S&OP • How we measured S&OP implementation • Fully implemented S&OP process • Decision makers participate in S&OP meetings • Organization follows S&OP process/plan • Further case analyses and interviews • Results in a nutshell • Many companies are trying (have tried), but only few succeed(ed)The objectives and the process are the same Use of the term S&OP is not meant to imply, in any way, any diminished importance of inventory planning Table of Contents S&OP Process Challenges3 5 Steps to S&OP Success5 Step 1 Innovation and Strategy Review 5 The S&OP process The process consists of focused review meetings for each discipline and an Executive meeting for decisions The diagram shows a standard model, but the actual number of review meetings are decided within each organisation For example Finance input is part of the preexecutive meeting

S Op Five Steps To Get Started Supply Chain Shaman

Sales And Operations Planning Relex Solutions

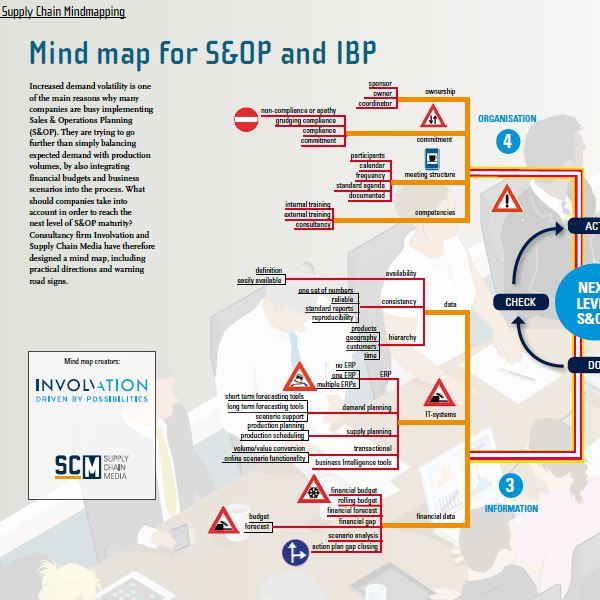

Monitoring the S&OP comes down to monitoring the assumptions Download Whitepaper 8 essentials of an S&OP Software Key Steps for Monitoring S&OP Performance The first step is to identify the key assumptions If the S&OP process includes promotions as in the CPG industry, promotion success may be criticalConsensus / Integration Review; Gartner says that one common issue to address right away is to identify the S&OE content in the S&OP process and move it to the S&OE agenda These need to be two separate processes, both clearly defined with purpose and scope The S&OP process focuses on the tactical horizon, typically from 3 to 18 or 24 months When developing the process timing, the key point

Achieve Excellence In Sales And Operations Planning Sapinsider

The 5 Steps That Will Transform Any Business From Profitless Prosperity To A Money Making Powerhouse Business Connector

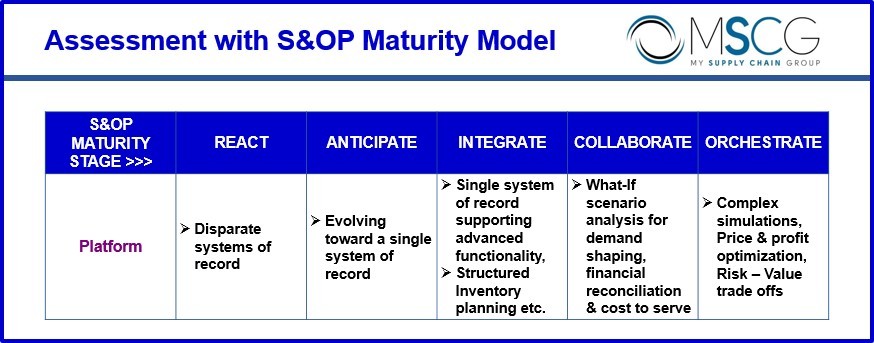

In this S&OP course International conference speaker and trainer Dr Muddassir Ahmed describes how S&OP Process can be used as the platform to drive continuoGartner, for instance, has reported that about 70 percent of global organizations are only in Stage 1 or Stage 2 of the four stage S&OP Maturity Model Most organizations acknowledge the need for a stepchange improvement to their S&OP process At the start of our journey, the S&OP process took six weeks to prepareDefinition is the first crucial step in any S&OP initiative With that in mind, consider the definition of S&OP in the APICS Dictionary, 13th Edition A process to develop tactical plans that provide management the ability to strategically direct its businesses to achieve

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Session 2 Forecasting And The S Op Demand Forecasting And Planning In Crisis July Shanghai Joseph Ogrodowczyk Ph D Ppt Download

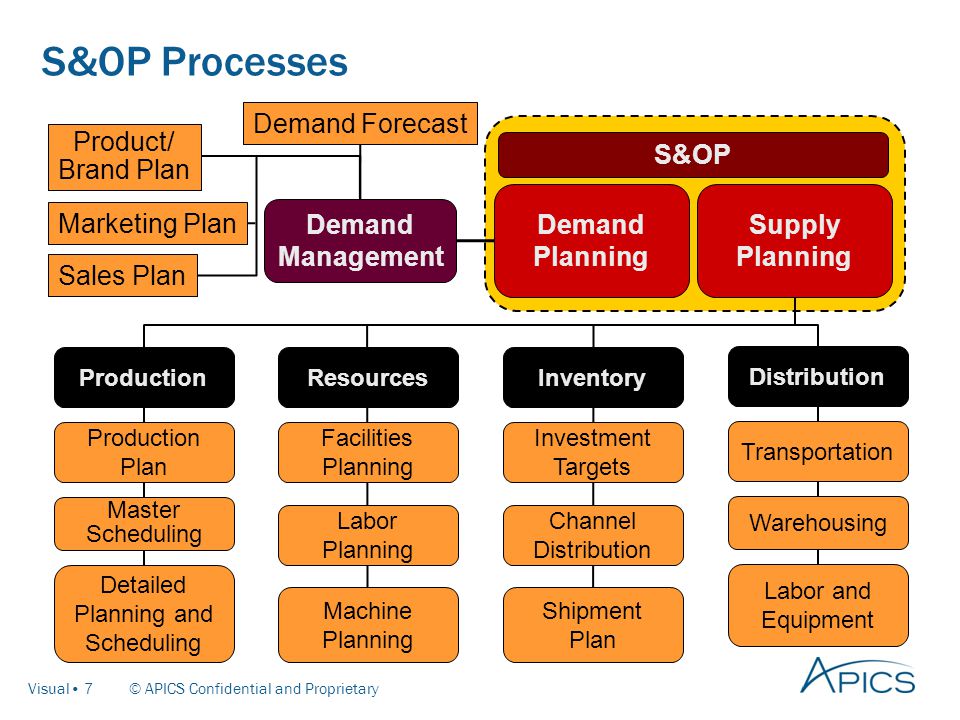

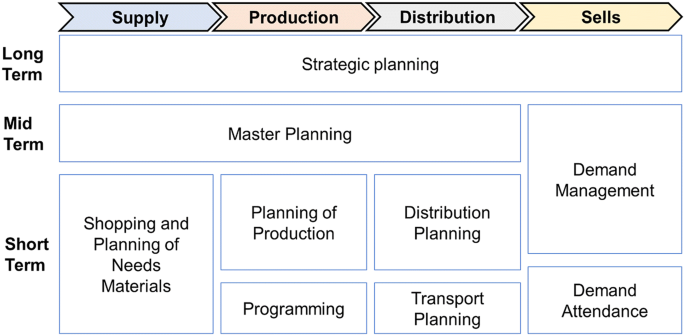

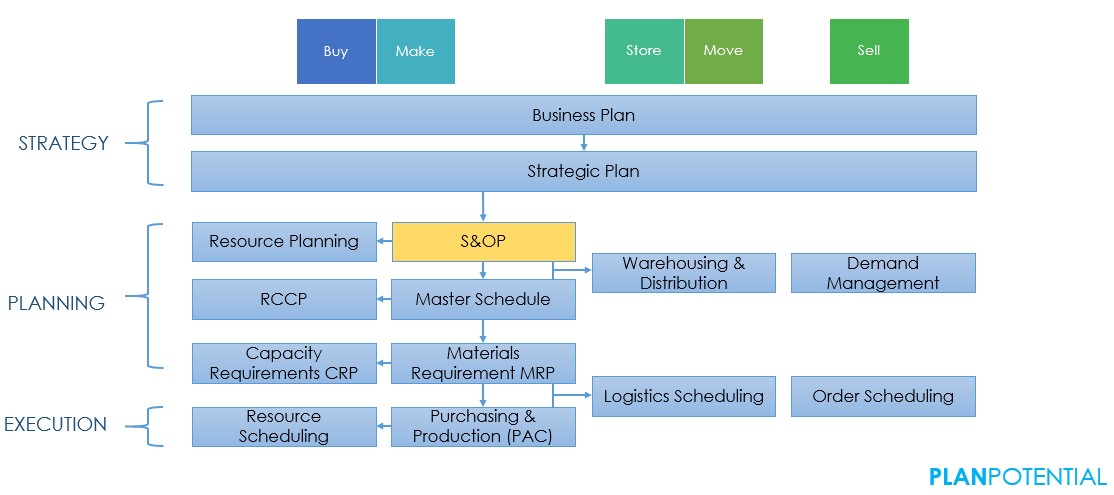

S&OP Integration with other Plans Source Adapted from "Operations ManagementProcesses and Value Chains", Krajewiski et al, 08, PHIL P Ltd, Milliken (07) and Lapide (04) identify S&OP asAll sources agree that one of the first steps to prepare for a successful journey up the S&OP maturity curve is mastery of demand This means really mastering the process and technology of forecasting demand, shaping demand and integrating the demand stream into the global planning processSales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment and synchronization among all functions of the organizationThe S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new product

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sales Operations Planning S Op Demand Planning Cargo

The first step is to improve the existing S&OP process to bestinclass Whether starting from scratch or making a few minor tweaks, the establishment of a strong S&OP process is the foundation for SI&OP The aspects of a bestinclass S&OP are also characteristics that make up a successful SI&OPThe 6 Steps of the S&OP Processes Product Review In this first phase of the S&OP process, planners involved in R&D, product development, and new product introduction analyze the health of products in the market, examine product pipelines, and arrive at decisions about product planning These decisions might include setting dates for new The following steps will help your S&OP team successfully move toward this new model 1 Establish an S&OE process that supports the S&OP cycle This usually doesn't require starting from scratch Examine your current S&OP cycle and identify all the activities that should fall under the S&OE umbrella

5 Steps Toward Successful S Op

Climbing The Sales Operations Maturity Ladder Stage 3 Consumer Goods Technology

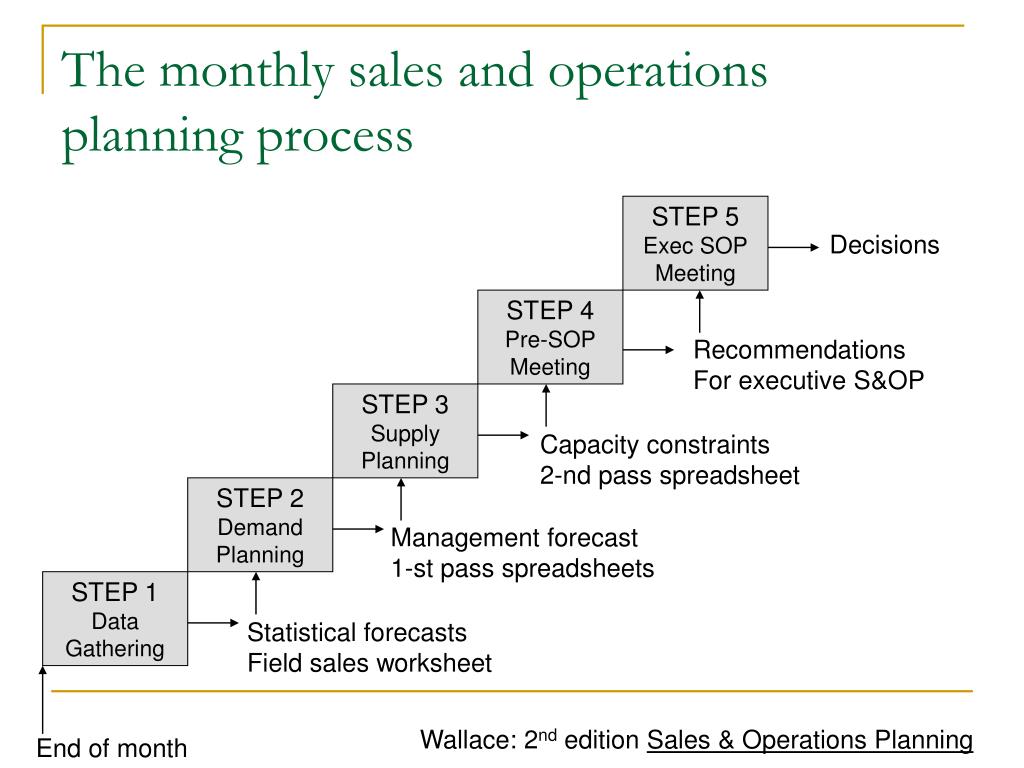

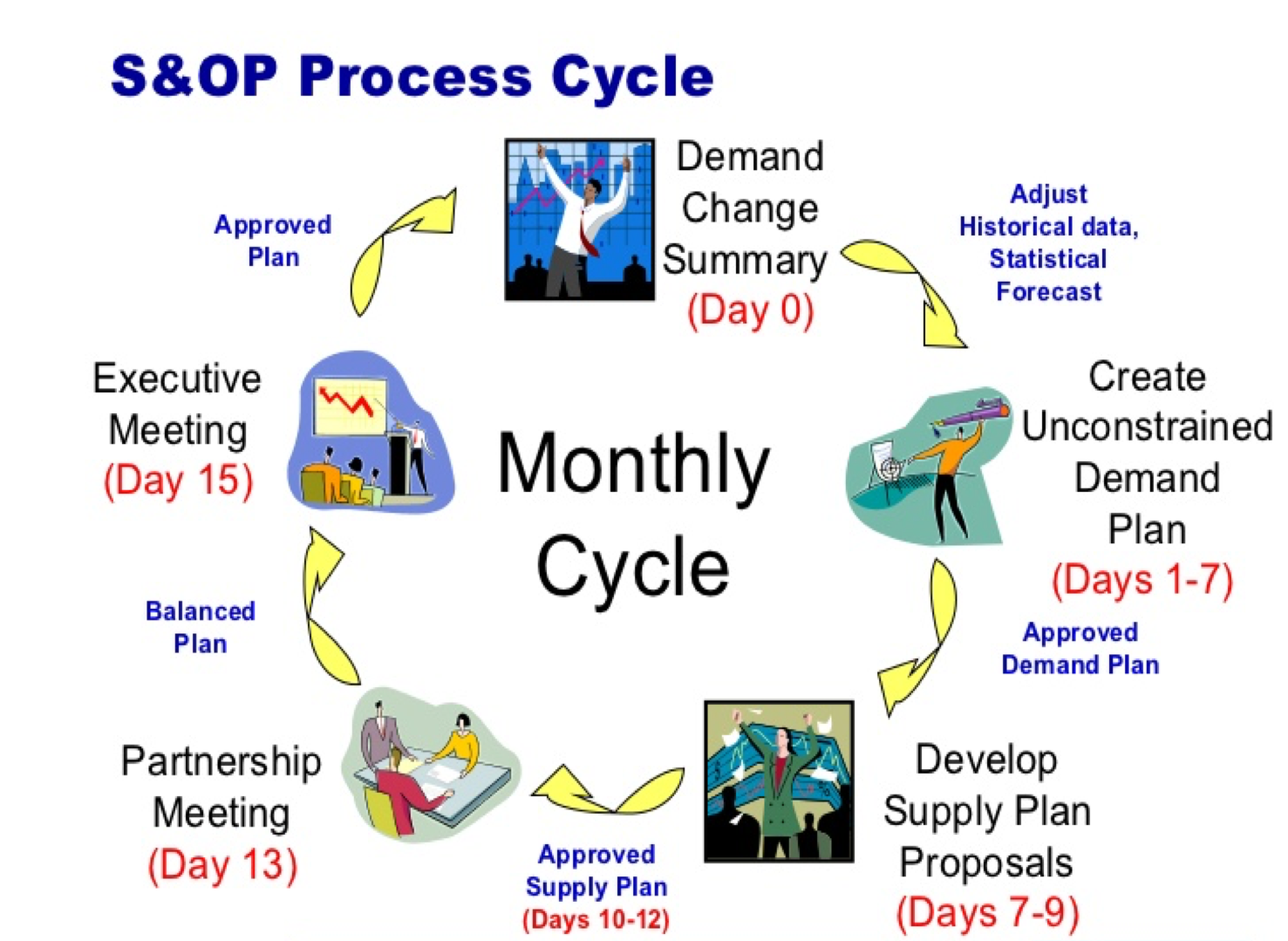

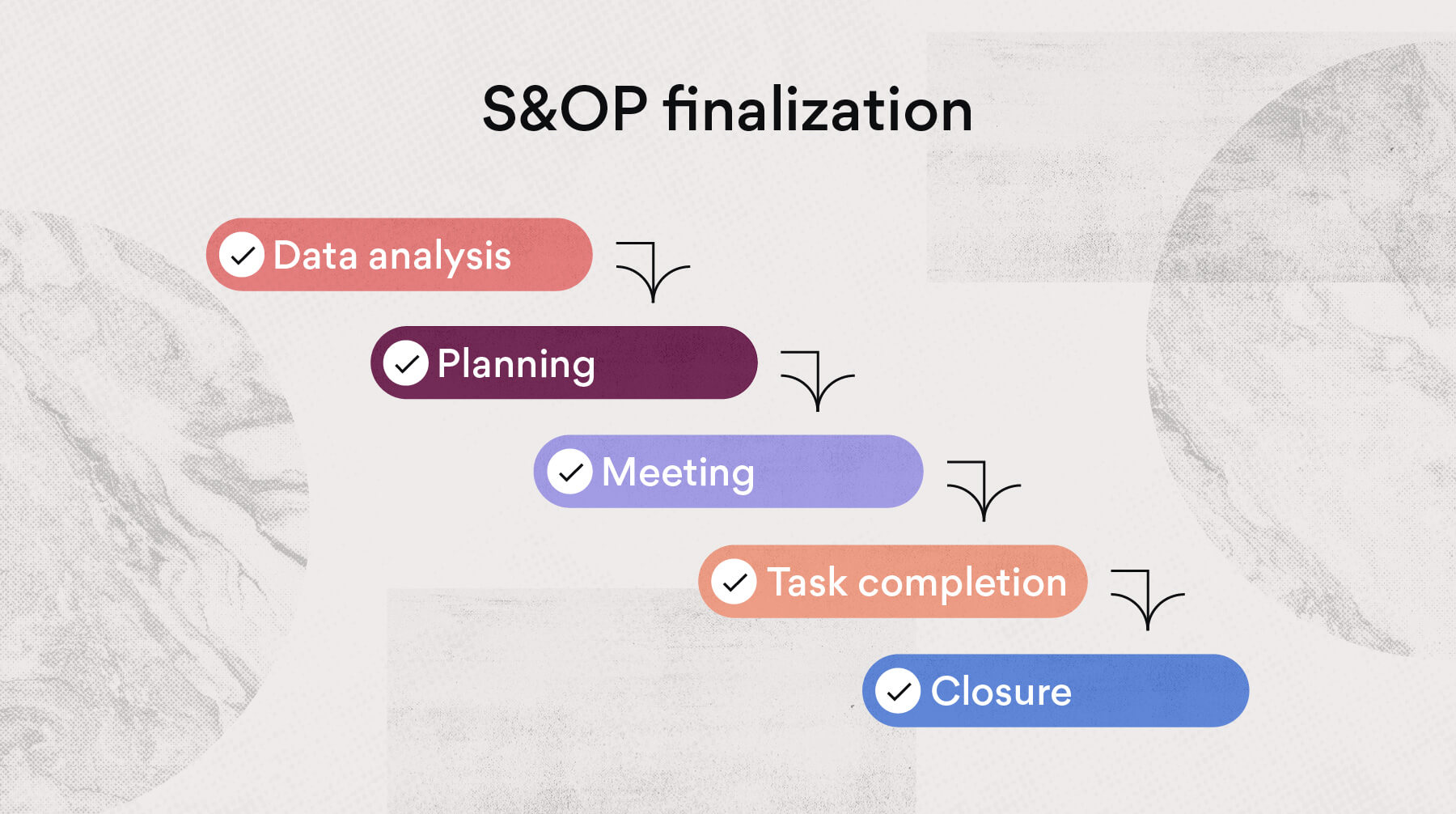

Define and orchestrate the S&OP process(s) Enable People to stay on top of relevant, contextual updates;S&OP, or sales and operations planning, is an integrated business management process that drives organizational consensus to balance supply and demand The S&OP process, which typically happens monthly, aligns operational areas – such as sales, marketing, product development, manufacturing, procurement, finance, and accounting – so they work in concert to meet financial A company might follow one of a few slight variations of the stepbystep S&OP process The accompanying graphic shows a monthly fivestep process data gathering, demand plan, supply plan, preS&OP, and finally the executive S&OP meeting, where decisions are made

What Is S Op Sales And Operations Planning Sap Insights

Apics Introduction To Sales And Operations Planning S Op Ppt Download

Data integration is a oneway highway The S&OP process should be separated from operational planning without losing the link, though The S&OP planning process should always be built on a realistic foundation, as the base line determines the trustworthiness of the S&OP plan You determine the pace and sequence of the steps in line with your own priorities So in fact, you can take a completely modular approach to implementing S&OP" Where does S&OP end and IBP start?Sales & Operations Planning Visibility Advanced Analytics Evaluation of multiple levers to shape profitable demand

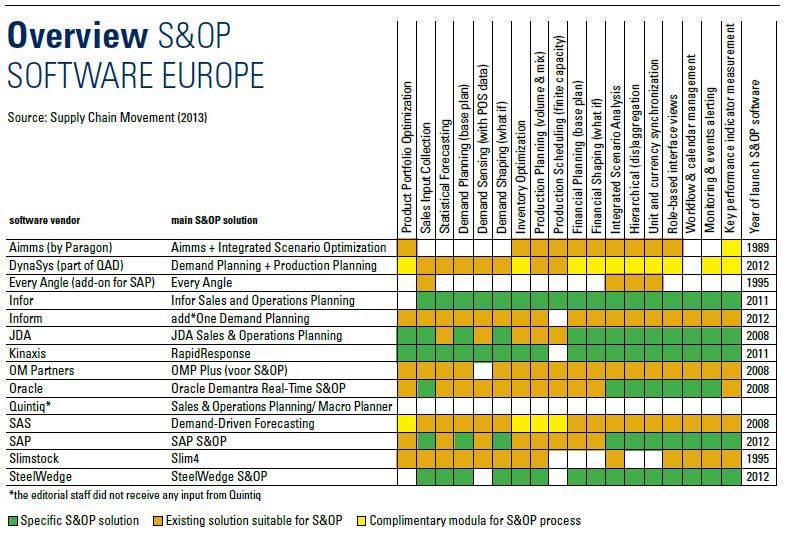

Software For Sales Operations Planning In Europe Supply Chain Movement

1

A Standard Operating Procedure (SOP) is a document that provides stepbystep instructions on how to complete a specific task properly An SOP may have several distinct parts to help organize and outline all parts of the process These parts may include a title, purpose (what), scope (who), responsibility (why), materials, and procedure (how)Content Covered in Session 3 Time 3513 S&OP as a major effort in orchestrating crossfunctional team's interactionsS&OP facilitator helps discover why opinions differ while keeping the S&OP process on track S&OP Silos Potential silo conflicts outside of the S&OP process that hinder S&OP performance conflicts of interest, such as one department lowering its costs by offloading expenses onto another department failure to share information, or

Pdf Sales And Operations Planning S Op An Overview

S Amp Op Training

To work properly, a process must be periodic Each months, several meetings needs to happen in order to reach at the end on the month an S&OP plan for the considered period This plan needs to be updated progressively depending on the meetings and the process We suggest to follow a 5 steps process for a full and efficient Sales & OperationSteps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1 S&OP Process Mapping Select the process Get the right people together Establish process boundaries List steps, activities and decisions Map the "asis" process Simplify the process Collect Data Is the process stable?

How To Run A S Op Process Benefits Process Steps Overcome Barriers Youtube

Common Sales And Operations Planning Myths Supply Chain 24 7

These include Timely and accurate communications across regions and functions To make certain this happens, adopt easytouse tools Align goals and objectives across regions and functions to ensure participants are not punished for shifting their focus Design and implement global IT support Contextually organize People, Documents, S&OP Process Steps, S&OP Data, Action items, Decisions, Alerts, etc around the S&OP Process;Regional & Global Executive reviews Review;

S Op Planning Services Chainsequence Inc

Scielo Brasil A Case Method For Sales And Operations Planning A Learning Experience From Germany A Case Method For Sales And Operations Planning A Learning Experience From Germany

General S&OP Steps While the sales and operations planning process can differ greatly among organizations, there tend to be certain major steps that virtually all planners follow The ones below were developed by Thomas Wallace and Robert Stahl, coauthors of the definitive guide, Sales & Operations PlanningIdentify the key wants/needs of your major players (Finance, Sales, Operations) and begin modeling a straw man process You may need to "dial it in" to continually improve the process Data collection steps We recommend using a highlevel SI&OP process that operates on a With a more mature S&OP process, it is about managing tradeoffs like these and other functions through structured process steps These usually include Product Review To discuss current and future product portfolio, New Product Launch/End of Life strategy and portfolio optimization as well as SKU complexity and component rationalization

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download

1 S Op Maturity Model Adapted From Grimson And Pyke 07 Download Table

Step 1 Map to Profit Center Leadership Drive Alignment to Business Goals The starting place is to build an organizational map by profit center For the greatest success, the S&OP process should report to a profit center manager The number of S&OP processes align to the profit center mapping

Smoother Execution Through S Op Logistics Management

8 Flowcharts For Traditional Planning Versus Advanced S Op Download Scientific Diagram

Advanced Planning System As Support For Sales And Operation Planning Study In A Brazilian Automaker Springerlink

Sales And Operations Planning For The Food Supply Chain Case Study Sciencedirect

What Is S Op How S Op Works Demand Planning Com

1

Ppt Sales And Operations Planning Powerpoint Presentation Free Download Id

What Is S Op How S Op Works Demand Planning Com

Scielo Brasil Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa De Material De Escrita Um Estudo De Caso Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa

Implement The S Op Process For Supply Chain Success Learn About Logistics

Sales Operations Planning Consulting Supply Velocity

2

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Sales And Operations Planning Process Self Assessment

Proposal Of A Model For Sales And Operations Planning S Op Maturity Evaluation

Amazon Com Sales And Operations Planning S Op In 14 Steps Ebook Pena Andres Cristina Kindle Store

Huge Step To Achieve Collaboration Within S Op Supply Chain Movement

Seven Steps To Support A Sustainable S Op Culture Supply Chain Minded

04 01 P2 Steps Of Sales And Operations Planning S Op Process Youtube

Sales And Operations Planning Report Do You Get Surprises

Ppt Uk S Op Process Powerpoint Presentation Free Download Id

Executive S Op Managing To Achieve Consensus Semantic Scholar

Scm Portal Insight The Five Steps Of S Op Process

How S Op Improves Your Organization Tmc Fr

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Supply Chain Update Successful Sales And Operations Planning In 5 Steps

Scm Awareness S Op Process Planpotential

Mindmap For S Op And Ibp Supply Chain Movement

Best Of The Best S Op Conference Ppt Video Online Download

How The Right Executive S Op It Tools Help You Flex For Growth Chainalytics

Supply Chain Graphic Of The Week The S Op Process

Data Quality As A Foundation For Your S Op Process

S Op Five Steps To Get Started Supply Chain Shaman

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations S Op Planning Initial Steps To Success Sales And Operations Planning Steps To Success Success

Sales And Operations Planning Supply Chain Business Solutions

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

1

Sales And Operations Planning Explorescm

This Is What Modern S Op Looks Like Demand Planning Com

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

0以上 S Op Demand Planning Meeting What Is S Op Meeting Gambarsae6p5

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

1

What Is S Op How S Op Works Demand Planning Com

Toc4u Focus 17

Generalized Scor Implementation

Measurement Challenges Related To Maturity Levels Of The S Op Process Download Table

Sitmi Science Industrial Technology And Management Intelligence S Op Sales And Operations Planning Process Flow Simple And Quick Explanation Of Each Steps Facebook

Successful Sales And Operations Planning In 5 Steps

Sales And Operations Planning A Project Manager S Guide Asana

Sales Inventory Operations Planning Si Op A Roadmap To Si Op Success Pragmatek Consulting

Sales And Operations Planning A Project Manager S Guide Asana

Sales And Operations Planning S Op In 14 Steps Cristina Pena Andres

Oracle Demantra Sales And Operations Planning User Guide

S Op Planning Services Chainsequence Inc

2

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Ametotonto 08 From Good To Great The Soplean

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

Sales And Operations Planning S Op 101 Smartsheet

Pdf A Case Method For Sales And Operations Planning A Learning Experience From Germany

2

Sap Sales And Operations Planning Software Product Xsop Pdf Free Download

Dp Vs S Op Process Flow

Best Of The Best S Op Conference

Achieve Excellence In Sales And Operations Planning Sapinsider

A Comprehensive Overview Of Sales And Operations Planning S Op

Ppt Sales Operations Planning Two Decades Of Learning At Basf Powerpoint Presentation Id

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Session 2 Forecasting And The Sop Demand Forecasting

Oracle Demantra Sales And Operations Planning User Guide

Achieve Excellence In Sales And Operations Planning Sapinsider

10 Essential Steps For S Op Success Farthing West

Sales And Operations Planning Business Forecasting Taruna Nagpal

Five Steps To Develop An Effective S Op Process Step 4 Balance Supply And Demand Supply Chain Link Blog Arkieva

Scielo Brasil A Case Method For Sales And Operations Planning A Learning Experience From Germany A Case Method For Sales And Operations Planning A Learning Experience From Germany

The S Op Framework S Process For Implementation Download Scientific Diagram

Huge Step To Achieve Collaboration Within S Op Supply Chain Movement

Ready To Upgrade Your S Op Process For Industry 4 0

S Op Five Steps To Get Started Supply Chain Shaman

Sales And Operations Planning A Project Manager S Guide Asana

0 件のコメント:

コメントを投稿